What is a flexible laminate?

Although many electrical grade laminates could, in principal, be considered a flexible laminate by definition … they may not necessarily be what is commonly referred to as a flexible laminate.

Historically a flexible laminate has come to refer to any 2 or 3-ply laminate consisting of Kraft paper (cellulose based), Rag paper (cotton based), non-woven PET fleece or mat (commonly referred to as Dacron®) or an aramid paper (the most common version is Nomex®) laminated to PET film (commonly referred to as Mylar®).

95% of the time there is a film of some sort in a flexible laminate. Other films that are used, though less commonly, are Kapton® or other polyimide, PEN, etc..

What are the laminate constructions that are available?

- DMD: Dacron Mylar Dacron® – 2, 3 and 5 mil Dacron® fleece or mats are most commonly laminated to any one of the various films list below.

- NMN: Nomex Mylar Nomex® – 2, 2.5, 3, 4, 5, and 7 mils are the most common thicknesses of Nomex® laminated to any one of the various films listed below.

- RM: Rag Mylar – 5, 7, and 10 mil are the most common thicknesses of Rag paper laminated to any one of the various films listed below.

- PET film thicknesses – 1, 2, 3, 5, 7.5, 10, 12 and 14 mils are the most common thicknesses of PET film laminated to materials listed above.

Why would I choose a DMD versus a NMN?

There are many reasons: all typically related to just two questions, what is the application and what is the temperature classification the material must meet, if there is one. Is the application a slotliner, top stick, slot separator, phase separator or is a non-electrical application having different requirements than typically associated with an electrical application. DMD typically occupies at least 1 temperture classification below NMN’s. Lastly, compared 1-to-1 DMD’s have a lower cost structure than NMN’s, however the two aforementioned reasons to choose one over the other must be addressed before cost can be.

Why would I choose a NMN instead of straight Nomex®? Or would I?

This again comes down to the same reasons as Why would I choose a DMD versus a NMN? It is based on application and temperature class. Likewise an NMN typically occupies at least 1 temperature classification below straight Nomex®. However since Nomex® is only available in certain thicknesses, if the desired thickness is not available in straight Nomex® as required by the design, an NMN must be investigated as an option.

Where are flexible laminates used?

Motor production, transformer production, automotive alternators, commercial and consumer generators, welding equipment, etc.

What are typical laminate applications?

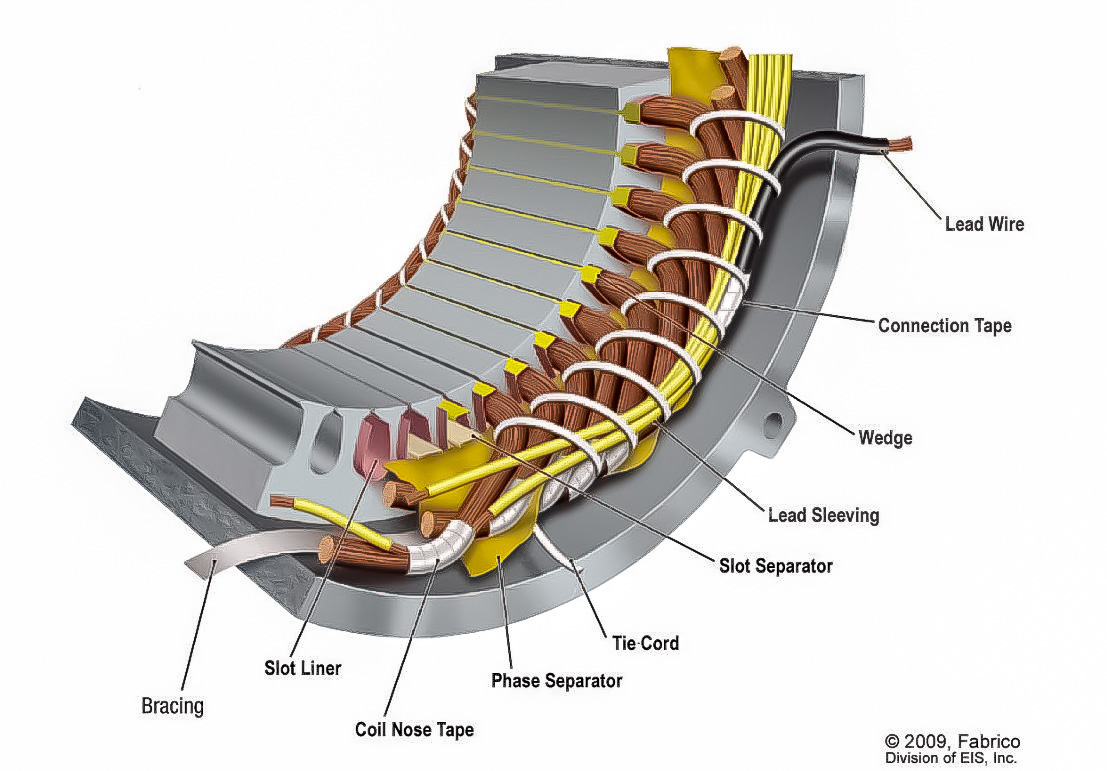

Wedges or top sticks, phase insulation, a slot liner, slot separator or non-electrical applications having different requirements.

How are the laminates sandwiched together?

The laminates are sandwiched together trough a lamination process involving precisely applied amounts of adhesive combined with a heat cycle in an oven sometimes followed by another coating and or post curing. It all depends on the type of material being produced.

Why do some laminates have stripes on them?

This is an identification process employed by some manufacturers with an identification purpose, while other manufacturers may use it for imitation purposes.

How can laminates be purchased?

- Rolls. What size rolls?

Typical widths are 36″ however wider materials are available for specialized application up to 72″. Flexible laminates lend themselves very well to be slit to nearly and width and length. This is one the characteristics that makes their end use so versatile. - Sheets. What size sheets?

Sheets are limited to the widths mentioned above and vary in length depending on what is required, however 24″ x 36″ and 36″ x 36″ are the most common sheet sizes.

Are there purchasing minimums?

This would depend on the channel through which the materials are procured.

Where are flexible laminates found in motors?